Radial Drilling Machines.

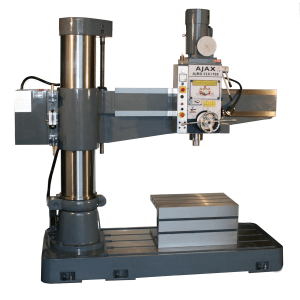

Ajax Radial Drilling Machines

Decades of Experience. Machines That Last.

Ajax has been manufacturing and supplying radial drilling machines since the 1950s, giving us over 70 years of expertise in building machines that stand the test of time.

With a comprehensive range of sizes and configurations, we offer a one-stop solution for all your radial drilling needs—whether for toolrooms, fabrication shops, or heavy industrial use.

Built to Last

Each Ajax radial drill is designed and manufactured for continuous operation—built to perform for the next 20 years without the need for repair.

- CE and CA certified for safety and compliance

- Engineered for reliability, strength, and accuracy

- Backed by decades of hands-on experience

Don’t compromise on quality.

📞 Call one of our experienced engineers today or

📧 Email us at sales@ajax-mach.co.uk to find the right machine for your workshop.

The castings of the Ajax AJRD radial arm drilling machines are made of high-quality Meehanite cast iron, reinforced with a system of crossed ribs and boxes. Additionally, all friction surfaces are hardened to 200 – 220 HB to reduce wear.

The bearing system allows for smooth rotation of the column, thus avoiding angular deflection of the spindle during clamping. A semi-automatic lubrication system provides lubrication for both the column and the elevating screw.

Specifications

Precision Spindle and Quill Assembly

Engineered for Accuracy, Stability, and Longevity

At Ajax, the spindle and quill assembly is at the heart of every radial drilling machine—engineered for maximum precision and minimal vibration.

- The spindle and quill are manufactured from specially forged, high-grade steel, chosen for its strength and vibration-dampening properties.

- The quill is fully machined, with gear teeth cut from solid and precision-ground to ensure long-term accuracy and smooth engagement.

- The spindle is mounted in double-row roller and thrust bearings, providing robust radial and axial support during heavy-duty drilling operations.

- A secure anti-vibration locknut is fitted at the top of the spindle to maintain spindle stability during prolonged use.

- The entire spindle/quill assembly is counter-weighted, allowing for balanced, smooth vertical movement throughout the drilling stroke.

This precision-engineered assembly ensures exceptional performance, reduced wear, and a longer machine life—even under continuous operation.

Hydraulic Clamping System

Precision Control with Effortless Operation

All Ajax radial drilling machines are fitted with a hydraulic clamping system as standard—excluding models 38 and 50.

- Clamping of the head, column, and arm is fully hydraulic and easily controlled via push-button operation, enabling smooth and secure positioning.

- The hydraulic system is intelligently divided to allow independent movement:

- The arm can be raised or lowered without affecting spindle alignment.

- The head and column can be unlocked separately, providing precise adjustment without disturbing other machine settings.

This system ensures greater flexibility, ease of use, and accuracy, particularly during setup and repositioning.

Fully Enclosed Headstock

Durable Construction with Precision Engineering

The headstock on all Ajax radial drilling machines is fully enclosed, housing the spindle drive and feed gearing for protection, durability, and reliable operation.

- A front-mounted feed wheel includes a built-in depth stop for consistent, repeatable drilling.

- Engagement of the feed is quick and simple—just pull the handles out to activate the mechanism.

- All gears within the headstock are made from nickel chrome steel, then hardened and precision ground to ensure long service life and quiet, smooth operation.

- An automatic lubrication pump continuously supplies oil to critical components, reducing wear and maintenance.

This robust design guarantees long-lasting performance and precision under heavy-duty use.

Electrical Control Panel

Safe, Accessible, and CE & CA Compliant

The electrical control panel is conveniently located on the rear side of the machine arm, ensuring easy access for maintenance and service operations.

- Designed and positioned in full compliance with CE and CA safety standards

- Well-organised layout for efficient troubleshooting and operation

- Protected and isolated from machining areas to enhance durability and safety

This setup ensures both operator safety and regulatory compliance, while maintaining easy serviceability.

Coolant Equipment

Integrated Coolant System

Efficient Cooling for Improved Tool Life and Performance

All Ajax radial drilling machines come equipped with a coolant system as standard to enhance machining performance and extend tool life.

- The system includes a high-quality coolant pump,

- Direct piping delivers coolant precisely to the drill point,

- Coolant is then efficiently returned to the sump for recirculation.

This ensures consistent cooling, improved chip evacuation, and prolonged cutting tool life—making it ideal for demanding drilling applications.

A Legacy of Drilling Excellence

From the Pioneers of the Past to the Precision of Today

The drilling machine has been a workshop staple for generations, with the radial drill evolving as one of its most versatile forms. Over the decades, legendary names such as Archdale, Asquith, Kitchen & Walker, Kitchen & Wade, WMW, and Bergonzi helped shape the industry.

Today, Ajax Machine Tools proudly carries that legacy forward—still here, still strong, and still delivering top-quality radial drilling machines designed to run trouble-free for the next 25 years.

Whether you’re continuing a tradition or starting a new one, give us a call to find out how we can support your machining needs.

📧 Email: sales@ajax-mach.co.uk

Gallery

Delivery, Installation & Training – We’ve Got You Covered

Our trusted delivery partners can transport and offload your machine using a variety of methods tailored to your site—whether that’s with a Versa-Lift or machine skates for precise positioning.

Once the machine is in place, our fully trained engineers will:

- Level and commission the machine

- Ensure everything is running correctly and safely

- Provide comprehensive training on operation and basic maintenance

From delivery to production, we support you every step of the way.

📞 Get in touch to arrange delivery and installation.