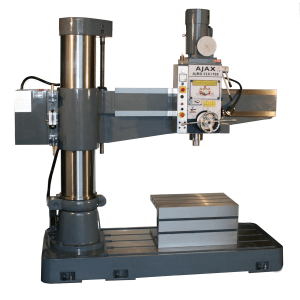

Radial Drilling Machines.

We stared manufacturing & selling radial drilling machines in the 1950’s. So we are very experienced in what makes a good machine. With lots of options and sizes we are the one stop shop. Give one of our engineers a call to discuss your next radial drill.

Designed & manufactured to run without repair for the next 20 years, why compromise. CE & CA Marked.

The castings of the Ajax AJRD radial arm drilling machines are high quality Meehanite cast iron, reinforced by a system of crossed ribs and boxes. Then all friction surfaces are hardened to 200 – 220HB to reduce wear.

The bearing system allows smooth rotation of the column, thus avoids angular deflection of the spindle when clamping. A semi automatic lubrication system provides lubrication for both column and elevating screw.

Specifications.

Spindles.

Our spindles and quill are manufactured from special forged steel and are constructed to reduce vibration. The quill is machined and the teeth cut from solid and ground to ensure accuracy. Then the spindle is mounted in double row roller and thrust bearings. It is then secured by an anti-vibration lock-nut at the top of the spindle. The spindle and quill assembly are fitted with a counter-weight to give smooth motion.

Hydraulic Clamping.

Hydraulic clamping is standard on the range apart from the 38 and 50. Clamping of the head, column and arm is actuated by a hydraulic clamps operated by push buttons. The hydraulic system being divided to allow the operator to move the arm vertically without affecting the spindle alignment and similarly unlock the head or column independently.

Headstock.

The head stock is a totally enclosed including the gearing for the spindle and feed mechanism. On the front feed wheel is a depth stop and the handles pull out to engage the feed. With all the gears are made of nickel chrome steel, hardened, ground and lubricated by an automatic lubrication pump.

Electrical System.

The electrical control panel is located on the back of the arm in compliance with the CE & CA norms.

Coolant Equipment.

Coolant equipment is supplied as standard, and consists of a pump complete with piping to the drill point and return to the sump.

History.

The humble drilling machine has been around for a very long time and the radial drill being a version of it. The names of the past include, Archdale, Asquith, Kitchen & Walker, WMW, Bergonzi to mention but a few, Ajax is still here still selling top quality machines designed & built to run trouble free for the next 20 years. So give us a call today to see what we can do for you. Or email sales@ajax-mach.co.uk